Axles & Gearbox: products

Parallel DRIVE AXELS

The position of the engine, electric or hydrostatic, directly assembled on the axle and placed parallel to its axis is the hallmark of these differentials, designed to answer to the manufacturers’ request of having groups with reduced dimensions in the longitudinal direction.

They are used in vehicles with load from 1.5 to 3.5 tonnes used for 4-wheel tractors, conveyors or mini-loaders. We can offer a “light versions” (M4M-A20 4stud bolts, M4M-A20 5stud bolts) with semi floating halfshafts suitable for wheels with a minimum d.b.c of 58mm, or alternatively the “stronger versions”, with full floating halfshafts and d.b.c of 102mm (M4M-A20 6stud bolts, M4M-A11,M4M-A12).

Available options are the hydraulic/mechanical drum brakes with high braking performances and a limited slip differential with a clamping coefficient up to the 60% .

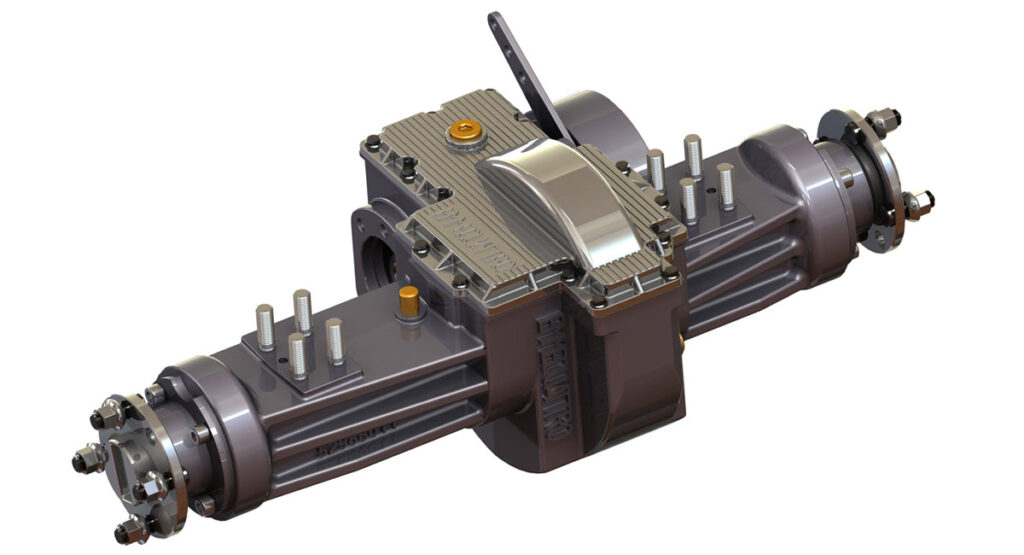

Parallel drive axle aluminium gearbox

This parallel axis transaxle with helical tooh ground gears is extremely silent and reliable. Ut’s been designed to equip electric transmission tractors.

This range of parallel-axis differential axles, designed for compact electric machines, represents the first response to the needs of a forward-thinking society: containment of harmful emissions, energy savings, and the use of eco-friendly and recyclable products. Special attention has been given to the sizing criteria of each component to ensure high levels of reliability and safety, even when used in demanding conditions. The overall efficiency of the axles approaches 95%, with noise emissions well below the limits prescribed for indoor and/or nighttime operation. For each model, numerous configurations are available, making the product versatile and adaptable to any application. The range consists of models with a Max allowable axle load of 30.000N and maximum electric motors, input ranging up to 4.000 rpm.

Parallel drive axle cast iron gearbox

With its 3 speed helical tooth ground gears, this transaxle is the parallel axis electric transaxle parent. It’s a quite flexible transaxle wich presents interesting customisation possibilities.

A spheroidal cast iron casing that allows to increase the max allowable torque up to the 32.000N.A very flexible configuration that permits to use 3or 2 stages gears, covering different ratios needs from i=1:12 to i= 1:37. All Gears have a grinded tooth profile, a special attention to the selection of bearings and design of components, has been given during the design of this serie, so the axle results particularly silent and efficient.

Both steering and rigid version are available. Each axle can be equipped either with brake disc or drum brakes, different options according to the braking efficiency need. An additional electromechanical brake at input brake different torque options as available, as well as a self locking system with a locking coefficient of up to 60%.

Parallel drive axles for hydrostatic motors

Designed for hydrostatic compact loaders where the motor can be directly flanged to the axle in parallel position and allows to make the most with the reduced available spaces. There are “light versions” (M4M-A20 4stud bolts, M4M-A20 5stud bolts) with semi floating half shafts suitable for wheels with a minimum d.b.c of 58mm, or alternatively the “stronger versions”, with full floating halfshafts and d.b.c of 102mm (M4M-A20 6stud bolts) A parking disc brake is available.4,46 or Ratios i=1:3.235 / 3.733/4,46. Available also a self locking system with a locking coefficient up to 60%.